BLOG

More related information

- Home

- Blog

- Knowledge sharing

- Factors Affecting 3D Measurement Results

Factors Affecting 3D Measurement Results

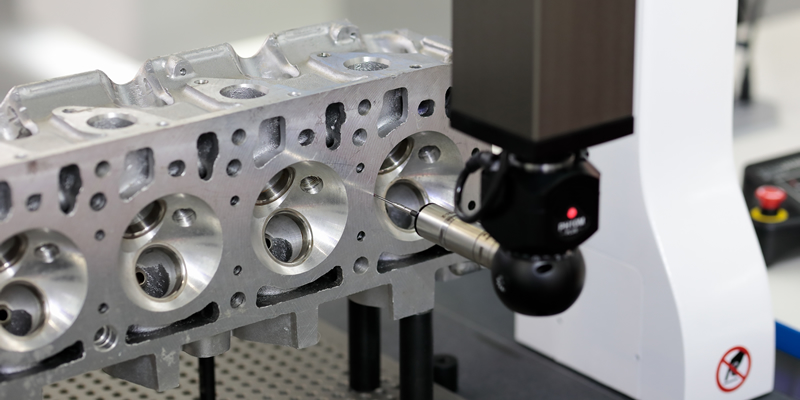

In the rapidly changing technology industry, or in the production technology of traditional industries, the pursuit of extremely high-precision products has become a common understanding between manufacturers and customers. Therefore, the measurement of workpieces has become extremely important, and "accuracy" has become a pursuit of products in the industry! When precision measurements are taken into consideration, Carmar measuring instruments are an indispensable piece of equipment.

When measuring the accuracy of workpieces, there are many aspects that must be taken into consideration. If there are procedural conflicts in small details of operation and technology, it may lead to differences in workpiece measurement from originally expected. In addition, when discussing that the measurement results do not meet expectations, the "reason" is also very important. >

When discussing three-dimensional measurement, precision and accuracy are the two most critical indicators. However, the factors that influence these indicators are often complex. This article will discuss some of the factors that mainly affect three-dimensional measurement results to help you gain a deeper understanding of how to optimize the measurement process to obtain more accurate and reliable data.

Measurement methods and strategies play a key role in three-dimensional measurement, and specific choices can significantly affect the final measurement results. Here are some further suggestions:

The influence of the operator's technical level on the measurement results cannot be ignored. Even if a high-precision measuring instrument is used, if the operator does not use the instrument correctly or does not understand the basic principles of measurement, errors may occur in the final measurement results. Therefore, regular training of operators to improve their technical level is a necessary measure to ensure the accuracy of measurement results.

When measuring the accuracy of workpieces, there are many aspects that must be taken into consideration. If there are procedural conflicts in small details of operation and technology, it may lead to differences in workpiece measurement from originally expected. In addition, when discussing that the measurement results do not meet expectations, the "reason" is also very important. >

When discussing three-dimensional measurement, precision and accuracy are the two most critical indicators. However, the factors that influence these indicators are often complex. This article will discuss some of the factors that mainly affect three-dimensional measurement results to help you gain a deeper understanding of how to optimize the measurement process to obtain more accurate and reliable data.

Accuracy of measuring instruments

The accuracy of measuring instruments directly affects the accuracy of measurement results. The accuracy of different brands and models of three-dimensional measuring instruments will vary. High-precision instruments can provide more detailed data, but may also require more rigorous calibration and maintenance. Regular instrument calibration is an important step in maintaining measurement accuracy. Ignoring this may lead to an increase in measurement errors.- The impact of measuring artifact strategies

- Sensor

- Measurement method

- Filter settings

Environmental factors

Environmental conditions such as temperature, humidity and vibration have a significant impact on the results of three-dimensional measurements. Changes in temperature will cause thermal expansion and contraction of the workpiece and measuring equipment, thus affecting the accuracy of dimensional measurement. The ideal measurement environment should maintain constant temperature and humidity while minimizing vibration interference. Generally speaking, the temperature of the measurement room should be maintained at 20°C+1°C, and the humidity should be controlled at 50%+10%.Material and shape of work piece

The material properties and shape of the workpiece also affect the measurement results. Materials have different thermal expansion coefficients and will expand or contract to varying degrees at different temperatures, which will directly affect the accuracy of the measurement results. In addition, the higher the complexity of the shape and structure of the workpiece, the more challenges may be encountered during the measurement process, such as difficulty in accessing certain detailed parts, which may lead to measurement errors.Measurement methods and strategies

Choosing appropriate measurement methods and strategies is critical. Factors such as contact point selection of the measurement probe, measurement trajectory design, measurement speed, and number of measurement points will all affect the final measurement results. Especially when measuring complex geometries, using the wrong measurement strategy can lead to inaccurate data. Therefore, before measuring, the best measurement strategy should be formulated based on the characteristics of the workpiece and the measurement requirements.Measurement methods and strategies play a key role in three-dimensional measurement, and specific choices can significantly affect the final measurement results. Here are some further suggestions:

Design reasonable measurement trajectories

The design of the measurement trajectory is crucial, especially when measuring complex geometries. The most suitable measurement path should be developed based on the geometric characteristics of the workpiece. Avoiding the probe from taking too long detours during the measurement process not only improves measurement efficiency, but also reduces cumulative errors.Control measurement speed

The choice of measurement speed should be adjusted according to the workpiece material and probe type. Too fast measurement speed may lead to poor contact between the probe and the workpiece surface, resulting in errors. Especially when measuring details, the measurement speed should be reduced to improve accuracy.Determine the distribution of measurement points

Choosing the appropriate number and distribution of measurement points is key. The measurement points should be able to represent the key geometric features of the workpiece, but the measurement points should also be avoided from being too dense to avoid increasing the measurement time and data processing complexity. For flat surfaces, the measurement points can be sparse, while in areas with dramatic geometric changes, such as curved surfaces or edges, the measurement points should be appropriately increased."Selecting and implementing appropriate measurement methods and strategies is the key to ensuring accurate three-dimensional measurement results"

The influence of the operator's technical level on the measurement results cannot be ignored. Even if a high-precision measuring instrument is used, if the operator does not use the instrument correctly or does not understand the basic principles of measurement, errors may occur in the final measurement results. Therefore, regular training of operators to improve their technical level is a necessary measure to ensure the accuracy of measurement results.

Conclusion

Based on the above factors, in order to obtain high-precision three-dimensional measurement results, multiple aspects must be considered and controlled. Choosing appropriate measuring instruments, maintaining stable environmental conditions, rationally selecting measurement methods, and ensuring that operators have professional skills are all crucial to the final measurement results. Only by comprehensively considering these factors can stable and reliable measurement data be obtained in actual production.Article Classification

Recent Articles

- Smart Manufacturing Era: The Future Power of "Precision Measurement"

- How to solve the problem that measurement tools are too complicated?

- Enjoying the Measurement Process: How Our Video Measuring Machine (VMM) Changes the Game

- The Evolution of Image Measurement

- Maximizing Precision: The Power of Advanced Video Measuring Machines